UltraGlass Technical Information

General Properties

UltraGlass is an extruded, high gloss, rigid thermoplastic material made entirely of Acrylic (PMMA – polymethyl methacrylate). It consists of a thick water clear top layer which has been permanently fused to a high colour solids layer. UltraGlass features include:

- Unique Integrated colour layer

- Fully recyclable polymer system

- High chemical resistance

- Excellent colour consistency

- Easy on site fabrication

- Easy to clean

- Repairable surface

- 5 year indoor UV warranty

Environment

UltraGlass is completely inert and does not release any emissions to the environment. UltraGlass is ultra hygienic and does not promote bacterial growth or transmission. UltraGlass consists of Carbon,Hydrogen and Oxygen and is recyclable by mechanical, chemical or thermal means.

UltraGlass can be ground and pelletised for re-use in sheet extrusion or injection molding.

If correctly incinerated UltraGlass produces only water and carbon dioxide. UltraGlass can also be chemically reduced to its original monomer for use in other acrylic based products.

Applications

UltraGlass sheet is suitable for many vertical surface applications around the home, office or Comercial environments. Typical uses include kitchens, bathrooms, laundries, partitions and vast array of interior features. UltraGlass can be applied to flat or curved surfaces.

UltraGlass is not recommended where a direct heat source is applied such as behind cooktops or in shower cubicles where aggressive cleaners are used. For more information on the installation of gas cooktops, refer to local standards or contact the appliance manufacturer.

- 2mm – Lamination, joinery and furniture

Protective Film

The top face of UltraGlass sheets are protected by high quality polyethylene film.

It is preferable to leave the protective film in position throughout machining, to keep the sheet surface in perfect condition. It is strongly recommended to avoid external storage. Protective film and adhesives could be damaged by UV exposure, which would make it difficult to remove the masking film.

UltraGlass Fabrication Information

Storage of sheets

Sheets must be stored in a dry place. It is advisable to place a polyethylene cover over the stack when a sheet is removed, to reduce moisture absorption. It is recommended that sheets of Ultra Glass be stored horizontally on their original delivery pallets, and that the pallets be placed on horizontal storage shelves. It is strongly recommended that pallets should not be stacked, which carries the risk of creating internal tensions and spoiling the flatness of the sheets.

If a vertical storage method is adopted, it is preferable that UltraGlass sheets be leaned against solid supports inclined at approximately 80° to avoid any bending.

It is strongly recommended to avoid storage longer than 6 months.

Cleaning

Best results are achieved by using a soft micro fibre cloth or chamois with a non abrasive soap detergent in warm water.

Do not rub the UltraGlass surface when it is dry. Do not use brushes, scrapers or scourers at any time. Grease or oil can be removed with kerosene. Avoid using window cleaning sprays or any acidic solutions. Do not use acetone, chloroform, benzene,Ammonia,Thinners, caustic soda, Toluene, Xylene, dichloromethane, amylacetate, glacial acetate acid, butyl alcohol, butyl acetate, cellusolve, cresols/ phenols, ethylacetate, chlorinated solvents, halogenated solvents, methyl alcohol, methyl ethyl keytone. Refer to Surface Re-finishing (page 7) to restore the UltraGlass surface to its original condition

Appropriate safety precautions should be used when handling UltraGlass sheets.

We recommend suitable gloves and safety glasses be worn at all times. Appropriate manual lifting and handling practices should be used with a minimum of 2 people at all times.

Machining

In terms of hardness, UltraGlass is similar to aluminium or light alloys. It can be machined (cut, milled, turned or drilled) using typical tools for either wood or metal.

Recommendations for machining

Excessively fast machining causes local overheating, generating internal stresses which must subsequently be relieved by annealing.

Best results will be achieved by using only very sharp tools, ensuring the efficient removal of swarf, not overheating the material.

During machining, parts must be clamped properly to avoid any vibration.

Strong vibration may result in a poor edge finish or broken sheet.

Some UltraGlass machining operations will produce hard and sharp swarf. Appropriate eye, hearing and dust inhalation protection must be worn by all operators during the machining or fabrication of Zenolite.

Cutting and other machining

When a sheet is being cut, the blade entry and exit stages are the most critical. A number of industrial cutting methods are suitable for UltraGlass.

Circular saws are normally used for straight cuts, with bandsaws or router cutters for other shapes. Other more sophisticated methods such as lasers or water jets give excellent results.

UltraGlass can be machined using numerous other processes such as drilling, routering, milling or sanding.

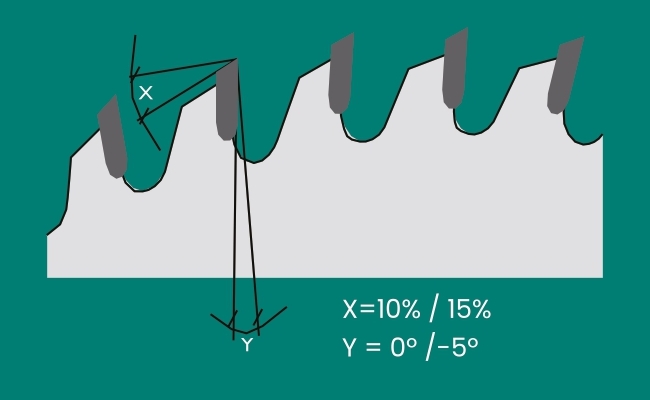

Circular saw

Circular saws give a straight, accurate cut. This is the most frequently used technique. When cut correctly, UltraGlass sheets have a clean surface.

Carbide-tipped blades are recommended for industrial use, for cutting piles of sheets.

The teeth are radial (the cutting edges are aligned with the centre) and are backed-off to form an angle of 45°at the tip. The teeth are not set but the saw must have a rake of approx 0.2 % on each face.

Pitch: 2 to 5 teeth per cm. Cooling by a jet of compressed air or water is recommended.

A polished finish can be obtained in a single operation if diamond-tipped tools are used.

Recommended Speed for different saw diameters

| Saw Diameters(MM) | Rotation Speed(RPM) |

| 150 | 6400 |

| 200 | 4800 |

| 250 | 3800 |

| 300 | 3200 |

| 350 | 2800 |

| 400 | 2400 |

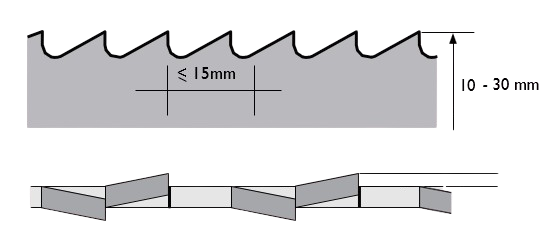

Bandsaw

Bandsaws should only be used to cut curves.

Bandsaws do not result in a clean edge and lengthy finishing operations are necessary to achieve a satisfactory finish. Woodworking machines with a blade speed of 15m to 25m/sec can be used.

Jigsaw

Jigsaws with blades suitable for wood or plastics can be used for short distances such as power point openings. Do not allow blade to overheat.

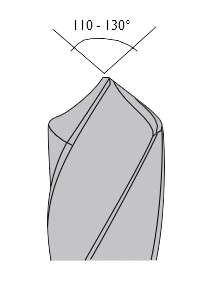

Drilling machines and bits

Drilling can be carried out with fixed or portable drilling machines, fitted with high speed, super-high speed or arbide-tipped steel drills for light metal, specially ground for UltraGlass.

It is recommended that the edge of the drill be ground parallel to its centre line, to suit the special characteristics of UltraGlass. Step Drills are ideal for larger diameter holes.

A DRILL SPECIALLY GROUND FOR ZENOLITE

STEP DRILL

Method

The use of carbide-tipped drills is recommended, to obtain a high-grade finish on the sides of the holes.

Best results will be achieved with a slow to medium drill speed. For more information go to www.UltraGlass.com.

Milling / Routering

Milling can be used to obtain complex shapes with a clean, polished machine finish. UltraGlass sheet must be securely held to avoid vibration and a poor edge finish.

It is advisable to use plain cylindrical milling cutters with two or more cutting edges, preferably one-piece carbide-tipped. High speed or super-high speed steel tools will give indifferent quality results.

The rotation speed must be between 10,000 and 30,000 rpm, depending on the diameter and number of cutting edges used, and compressed air cooling may be helpful.

Feed rates of 12m to 15m/min are suitable.

Milling can be used for several operations such as:

- Cutting through

- Engraving

- Finishing edges

Engraving

Engraving can be carried out using computer controlled milling or laser equipment. Removal of large areas of the colour layer may result in deterioration of the clear layer.

Always conduct a trial of any new engraving design prior to proceeding to production.

Sanding

Sanding is required to finish the edges of coarsely cut sheet. Wet carborundum paper is used, either by hand or on a disc or belt sanding machine. For the latter, the recommended belt speed is 10 m/sec. A water spray should preferably be applied during sanding, to minimise overheating of the material. It is preferable to proceed in stages, using in turn:

- A coarse-grain abrasive paper (e.g. 100)

- A medium-grain abrasive paper (e.g. 220)

- A fine-grain abrasive paper (e.g. 500)

After sanding UltraGlass can be polished to a high gloss finish using either manual or machine methods if required.

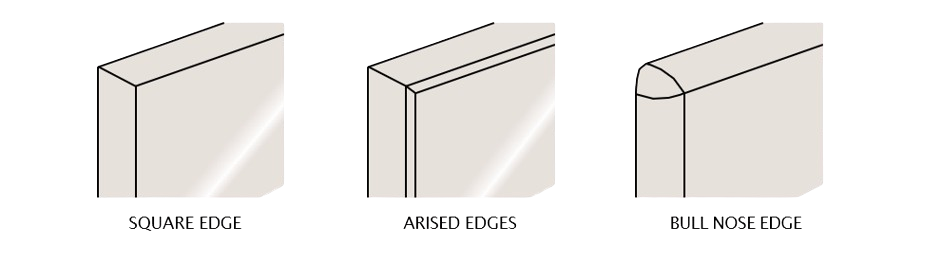

Edge Finishing

- Edges can be finished square, arised or bull nosed (see diagram next page). For best results, edges should be sanded & polished after shaping (Refer Polishing and Re-Finishing Instructions on the UltraGlass(web site www.swpi.co.kr)

- A wide variety of edge bands, aluminium and plastic trimming can also be used in conjunction with UltraGlass. UltraGlass sheets are also compatible with many standard aluminum framed door systems for cabinets, wardrobes etc.

- Allow 3mm/1000mm clearance between UltraGlass & the frame

- Do not use PVC edge trimming or gaskets at any time

3 types of edges

Polishing

Machine polishing

UltraGlass edges can be polished using diamond tipped router cutters or specialist diamond polishing machines. UltraGlass edges can also be polished with a felt-belt or disc polisher using cotton or flannel buffs combined with a suitable polishing paste.

Machine speed below 3000rpm is preferred to avoid overheating and deforming the UltraGlass.

Laser Cutting

This process offers many advantages:

- It allows most shapes to be produced extremely accurately

- It minimises off-cuts

- It gives an excellent edge-finish, generally requiring little or no final polishing. Differences in quality of the cut depend on the source and power of the laser and the speed of cut.

Laser cutting causes high internal stresses, which mean there must be no contact with solvents (adhesives, harsh cleaning products, etc). Annealing will reduce the risks of crazing. It is not recommended to use adhesives in conjunction with laser cutting.

Water-jet cutting

This process offers similar advantages to laser cutting, except for the edges which are not glossy in appearance. An additional advantage is that there are no internal stresses near the cut edge.

Contact with solvents is permissible, including adhesives

Dimensional variation and expansion gaps

UltraGlass has a coefficient of expansion roughly 10 times that of metals 0.7mm/1000mm/10°C. Consequently, the sheet must be cut to dimensions which leave sufficient space for expansion and contraction. This applies to the length and width of the sheet and to the diameters of fixing holes. As a general rule allow 3mm/1000mm for thermal movement.

Where the sheet is fixed by screws, the following guidelines are recommended:

- The drilling diameter should be substantially greater than the diameter of the screw thread

- The hole must be protected from the screw threads by a plug made of compatible material (PE type)

- Soft insulating EPDM-type washers should be used when screw fixing

Incompatibility with other materials

UltraGlass must not be placed in contact with incompatible plastic materials such as plasticised P.V.C. or silicone sealing compounds containing acetic acid or acetates.

Recommended contact products are: Teflon®, Dutral®, EPDM rubber, neoprene, butyl, polyethylene (PE), polypropylene (PP) and neutral silicone.

Lamination

UltraGlass 4mm and 2mm can be laminated to a variety of substrates using several different adhesive types. Hand and machine lamination methods are available.

order to achieve a suitably flat panel.

UltraGlass must only be laminated at ambient temperature using nib rollers or cold pressing in Refer to

| Property | Test Method | ASTM Test Reference | Test Specification | Test Frequency |

| Surface and General Imperfections | — | — | Take 1x Full SheetStanding 0.5m away from the sheet at optimum angle – Count visible lumps, low spots and black specks in reflective lightSurface quality for sheet face area Specks, pimples or raised sections will not be grouped closer than 500mm 8 Specks <0.8mm; 8 pimples or raised section <3mm No obvious die or flow lines; No scratches or repeat marks No pin holes >0.2mm Visual assessment in moderate interior lighting Board viewed in a vertical condition from a distance of 1000mm A) If; ≥ 6 In total of lumps and low spots Take another immediate cut sample and check. If still no good, put on waste until production rectifies the problem. B) If; ≥ 5 Black Specks Put on waste straight away until production rectifies the problem. | Every 30 min If A) or B) is out of spec: Change test frequency to Every 15 min until 2 consecutive results are in spec Ring Production Manger if supervisors cannot fix the problems |

| Saw Cut | — | — | Cut edge to be parallel with no cracks larger than 5 mm | 1 Hourly |

| Saw Dust | — | — | Sheet must be free of any dust ENSURE NEUTROVAC IS FULLY OPERATIONAL | 1 Hourly |

| Masking | — | — | Type: Refer to Work Order | |

| General masking quality No wrinkles, scratches. Good adhesion and fully covered | Every 30 min | |||

| Inkjet Printer | Visual | — | Type: Refer to Work Order | 2 Hourly (or at least once on every order) |

| Thickness | Micrometer | — | Please refer to MS-085 | 1 Hourly |

| Length/Width | Tape Measure | — | Length: Between – 0 to + 7mm Width: Between – 0 to + 3mm | 1 Hourly |

| Measure length on both sides ≤ 2mm difference | Every 30 min | |||

| Squareness | Tape Measure | Diagonal Difference ≤ 2mm | At least once per Shift | |

| Colour | TS-075 | — | Check Reflectance on all the colours OR Check Reflectance AND Transmittance on the light colours Refer to MS087 StyleLite Colour Tolerance | 1 Hourly |

| Gloss Level | Glossmeter | — | All colours except CLEAR Velvet ≤ 20 Gu @ 60° TruMatte ≤ 8 Gu @ 60° CLEAR Velvet ≤ 25 Gu @ 60° Measure Left, Middle and Right across the sheet | 1 Hourly |

| Dyne Level | Dyne tester kit | — | ≥ 50 MAKE SURE CORONA TREATMENT UNIT IS SET FOR OPTIMUM RESULTS | Once per Shift |

| Co-extruded Layer Thickness Check | TS- 072 | — | >30 μm Across the sheet | As Requested |

BALANCING OF LAMINATED BOARDS

TECHNICAL GUIDELINES

OVERVIEW

In general, the lamination of thermoplastic materials onto primarily wood-based substrates such as MDF/ Plywood / Particle board or other materials requires consideration of balancing the board to prevent board warpage. This is far more a technical requirement with thermoplastics Décor faces i.e., Acrylic/ABS/ PETG than what is seen with bonding of thermosets such as HPL and Phenolics.

BACKGROUND

In general thermoplastics such as high gloss acrylic décor sheet or ABS sheet expand and contract with temperature changes. The force they can exert when laminated on a board can be enough if not correctly balanced, to cause warpage or bending of the laminated board. This is more usually evidenced in larger panel applications like wardrobe doors and long cabinet cupboard doors (shutters).

Balancing the board in the lamination stage ensures that the effects of the thermal expansion characteristics of the face or “show” Décor are mitigated by either balancing the board with a material that closely matches the thermal expansion coefficient of the face material or with a material that has enough dimensional strength that can resist or effectively nullify the face material expansion and contraction.

GUIDELINES

There are many considerations that must be examined in choosing the correct backer material for effective balancing. These include but are not limited to

- Final size of the shutter panel. Long shutter panels such as 2000mm x 500mm are more prone to warping than say a typical kitchen shutter at 700 x 600mm

- The substrate used … well composed/ calibrated plywood has more resistance to differential forces from the laminated face material than pine based MDF which in turn has more resistance than rubber wood based MDF

- Thickness of the panel… The use of a 9mm substrate will have a higher propensity to bend than say a 16mm substrate

- The environment the panel will be installed in… an alfresco kitchen in an outside cooking area may experience large temperature variance comparative to say an ordinary internal kitchen panel

- Attachment of handles and other hardware.

- Gauge thickness of the face Décor material

BALANCING RECOMMENDATIONS

- For thinner thermoplastic-based Décor foils such as 0.5mm – 1.0mm Acrylic Hi Gloss or Acrylic Matte effective balancing can be achieved with a similar gauge thermoplastic sheet such as Backer ABS or even two-sided Décor application at same gauge i.e., Face Décor is 0.8mm Hi Gloss Acrylic Backer Décor is 0.8mm HPL

- For Thermoplastics greater than 1mm in gauge up to 2.0-2.5mm, effective balancing can be achieved by either a backer of similar gauge matching the front/ show Décor gauge or by using a slightly lower gauge thermoset material such as HPL

- For example, depending on the application a 1.2mm Acrylic sheet face can be balanced by use of a 1.0mm HPL backer, a 2mm Acrylic sheet face can be balanced with a 1.25mm HPL backer

- As the gauge of the substrate decreases the backer should be closer in gauge to the face / show Décor .. i.e on 9mm MDF substrate a 1.5mm acrylic face décor would need a backer similar in gauge if a thermoplastic backer is chosen or a 1.2/1.3mm thermoset backer such as a HPL.

- All of the above are guidelines only, consideration of proper effective balancing should be decided based on many factors

HANDLES and HARDWARE

- The attachment of handles and other hardware needs to be considered as it pertains to balancing

- This consideration becomes more critical with larger panels such as wardrobe doors and tall cabinetry as well as length/ size of the hardware to be attached

- In general handles on long panels or indeed long handles on any size cabinetry should not be firmly attached ( locked in) such that effectively you have locked in the hardware to the substrate .

- In these cases, over drilled holes should be used with rubber or silicon expansion grommets employed such that the panel is not locked in as it pertains to expansion and contraction.

- The need to adopt this becomes more critical as a function of both the overall panel length and the overall hardware attachment length

- The concept here is to minimize panel ‘lock-in” by the hardware attachment